Composite materials

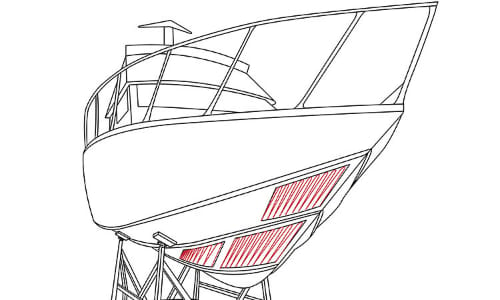

We manufacture heating blankets for mold heating during pre-processing or rest phases, as well as heating systems for composite material processing.

Rimatek’s mold heaters are designed according to customer specifications and can be produced in any size, with surface temperatures ranging from 10°C to 250°C and power supply voltages from 12V to 400V.

The heating blankets can be easily adapted to molds used in the production of composite materials (curing), soles, shoes, chairs, and more.

Preheating molds, particularly those for composite materials, is useful to maintain high material quality and prevent defects and waste.

This type of industrial heating blanket process for molds improves the handling of resins, carbon fibers, and polymers.

Heating composite materials during the post-curing phase (processing and application of the composite) is especially beneficial to achieve the proper temperature curve for the raw material, ensuring correct curing times.